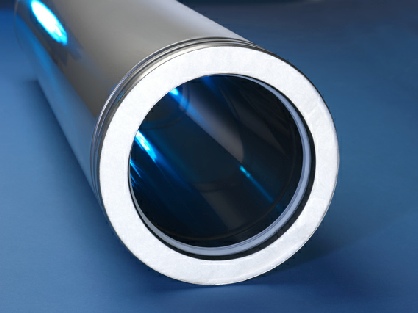

TWIN WALL PRODUCT

*SUITABLE FOR CONDENSING APPLIANCES

* ON CONDENSING APPLICATIONS THE SYSTEM MUST BE FITTED WITH A MINIMUM 3 DEGREE SLOPE BACK TO THE APPLIANCE/S (REFER TO CATALOGUE)

Fuel type: Oil/wood/coal/pellets normal (wood)

Sealant: To be removed before installation, as well as the cap and door seals.

MF RANGE

Applications

- Atmospheric gas-fired boilers

- Condensing boilers

- Wood-fired stoves

- Industrial ovens, large-scale establishments

Advantages

- Universal chimney/flue system

- Inner- and outer wall from high quality stainless steel

- No thermal bridges, uninterrupted insulation from base plate to top stub

- Stress free thermal expansion

- Fast-build system without the need of sealants

- Compatible with system ME

- High density and high quality insulation

- High-temperature silicone sealing ring

- Lightweight elements

- Immediately ready for use

- Chimney fire resistant

Technical characteristics

EMAIL: sales@sigram.co.uk

HEAD OFFICE: 0161 682 1999

Inner Diameter (mm) | 100 | 130 | 150 | 180 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 |

Outer Diameter (mm) | 150 | 180 | 200 | 230 | 250 | 300 | 350 | 400 | 450 | 525 | 575 | 675 |

Cross Section (cm 2) | 79 | 133 | 177 | 254 | 314 | 491 | 706 | 962 | 1256 | 1590 | 1963 | 2826 |

Weight (kg/m) | 6 | 7 | 8 | 9 | 10 | 12 | 16 | 19 | 21 | 26 | 28 | 34 |

Application:

Operating Mode:

Pressure :

Max. working pressure:

Operating temperature:

Max. temperature allowed:

Inner wall

- Material

- Thickness

Outer wall

- Material

- Thickness

Insulation

- Type

- Thickness

Chimney/Flue System

Dry/Wet

Negative/positive pressure

5000 Pa

600 Degrees C (N)

200 Degrees C (P/H)

1000 Degrees C(N)

(max. 30 min.)

200 Degrees C (P)

AISI 316L/EN 1.4404

up to 250 dia: 0.4 mm

from 300 dia: 0.5 mm

from 450 dia: 0.6 mm

AISI 304/EN 1.4301

up to 250 dia: 0.4 mm

from 300 dia: 0.5 mm

from 450 dia: 0.6 mm

Mineral wool

up to 400 dia: 25 mm

from 450 dia: 37.5 mm

QUALITY FLUES SINCE 1969